Blogs

ViewTec FRD coating

ViewTec FRD coating

For over two decades, ViewTec has relied on the enduring efficacy of ViewTec® FRD coating across rigorous applications. Today, we are thrilled to unveil our successful integration of this formulation within our own facilities. Not only do we offer this cutting-edge coating for sale, but we also provide expert application services directly to our customers. Some of the key benefits include:

- Outstanding antifog properties which fully comply with EN166:2001

- Permanent anti-fog performance. The antifog does not degrade over time, even after years of service the functionality remains

- Suited for optical applications such as goggles and visors

- PFAS-free and REACH compliant

- Short curing time: 5 minutes

ViewTec FRD stands as a PFAS-free solution, crafted specifically to fortify surfaces with a resilient finish. This transparent coating excels in delivering enduring anti-fog capabilities alongside robust abrasion resistance. Fully adhering to EN166:2001 standards, it distinguishes itself from conventional anti-fog coatings by operating through water absorption rather than water spreading or repellency. This unique approach ensures a lasting anti-fog performance. Moreover, ViewTec FRD surpasses stringent requirements for visors and respiratory masks, including compatibility with dishwasher-like cleaning programs commonly utilized by in example firefighter departments.

Application of the coating

The ViewTec coating is compatible with both dip and flow coating techniques. However, to ensure optimal long-term adhesion to polycarbonate and glass substrates, a primer is required. ViewTec Coatings meticulously evaluates and quantifies several primers specifically designed to foster enduring adhesion between the substrate and the top coat. Notably, these primers are waterborne, aligning with our commitment to environmentally conscious solutions.

Water repellent anti-fog mechanisms

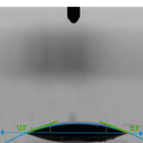

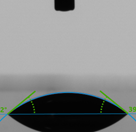

For water spreading or water repellent anti-fog mechanisms, the water contact angle (WCA) method is an excellent analytical tool to study the dynamics of such a coating.

In the depicted images, a distinct water droplet, resembling the shape of a droplet deposited by a needle, is observable. The left image captures the moment at t=0s when the droplet first touches the surface, while the right image, taken at t=1s, illustrates the rapid spreading of the droplet into a thin, transparent film of water, ensuring unimpeded visibility. Thus, when water vapor from exhaled air condenses on the surface, it swiftly interacts with the condensed water to maintain clarity.

The activation mechanism of these coatings varies depending on their chemical composition. Some coatings require wetting to become activated, while others react immediately upon contact with condensed water. However, a notable drawback of such coatings is their limited durability. Cleaning with polar detergents containing surfactants can significantly compromise the anti-fog functionality by causing the coating to react unfavorably, either by swelling or altering the surface chemistry. Consequently, contact with detergents poses a critical risk to the longevity of articles coated with these formulations.

Unique waterborne coating formulation

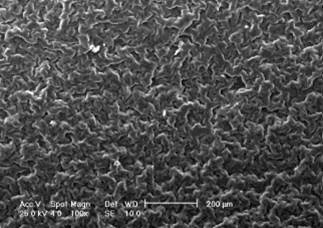

Therefore, the ViewTec FRD operates on the principle of water absorption. Through a distinctive waterborne coating formulation, it creates a robust and enduring anti-fog surface enhancement with abrasion resistance. Under magnification, the surface reveals a distinct morphology, as depicted in the microscopic image below.

Traditional water contact angle measurements are ineffective for quantifying the anti-fog mechanism on these surfaces. This is because water vapor does not condensate on the surface; instead, it is promptly absorbed by the coating’s surface. This unique mechanism renders the surface relatively inert to repeated cleaning with polar detergents containing surfactants. Unlike coatings operating on the liquid state of water, the ViewTec FRD coating functions on the gaseous state of water, enhancing its resilience to cleaning processes.

Intrigued by this unique chemistry please contact ViewTec Coatings. Your partner for coatings, coating application and coating development!

Goolderheideweg 11,

3950 Bocholt

+32 (0)89 46 93 30

info@zweko-optics.com

BE0840.886.961