Blogs

Polycarbonate as glass material

Polycarbonate as glass material

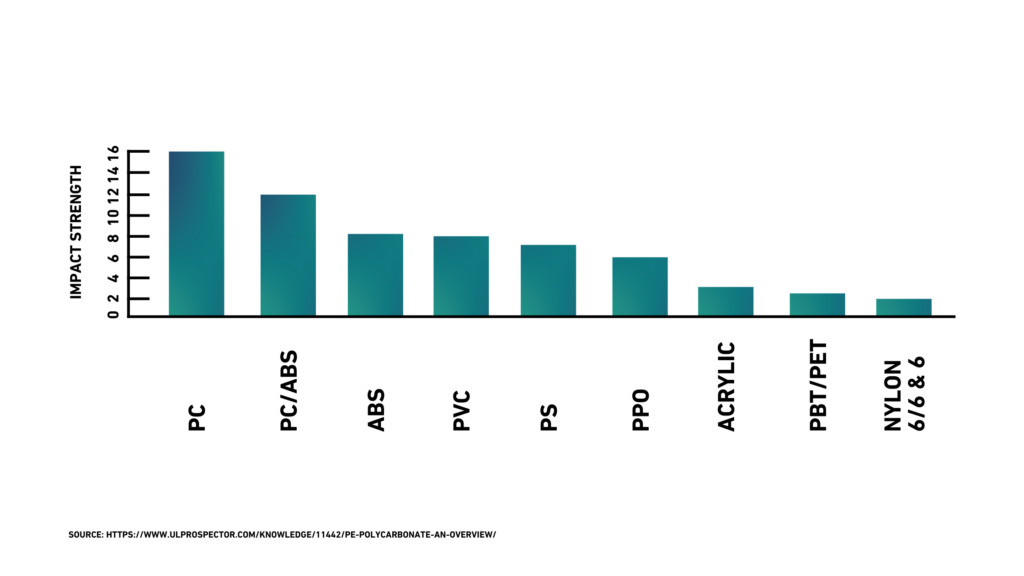

When looking for impact-resistant glazing material, Polycarbonate (PC) is often the obvious solution. This is because the impact resistance of polycarbonate is 250 times higher than that of window glass. The toughness of polycarbonate is remarkable compared to other transparent plastics, such as PMMA or SAN.

Known applications of polycarbonate

Not only the channel sheets for conservatories and stadiums are a known application of polycarbonate as a glazing material, but also bulletproof glass.

What about wear and tear on the polycarbonate?

However, polycarbonate also has some drawbacks. For outdoor use, it is not ideal and it is poorly resistant to chemicals and abrasion. However, those disadvantages can easily be addressed by applying surface enhancement, by means of coating layers that is! Coatings create abrasion resistance comparable to glass.

Problem solved, but it is still very important to choose the right coating. There are different types of coatings that can protect the polycarbonate, but to preserve the properties of the polycarbonate, it is important to weigh up this choice carefully.

Which coating do I choose for polycarbonate?

One of ViewTec’s specialities is applying UV-curable coatings to polycarbonate. These have high abrasion resistance, but also preserve the impact performance of the polycarbonate. To prove this, several tests were carried out. Surely the best results were obtained in the multiaxial impact tests at temperatures down to – 40ºC.

This is a type of impact test in which energy is transferred in a very short time (milliseconds). You can compare this, for example, to when a pebble hits the windscreen of your car, or when a burglar tries to smash the window of a shop.

That test is defined according to the international standard ISO 6603/2. Polycarbonate is the only transparent thermoplastic material that shows no sign of embrittlement in a temperature range varying from -40ºC and 80ºC.

Find the best coating for your polycarbonate glazing at ViewTec

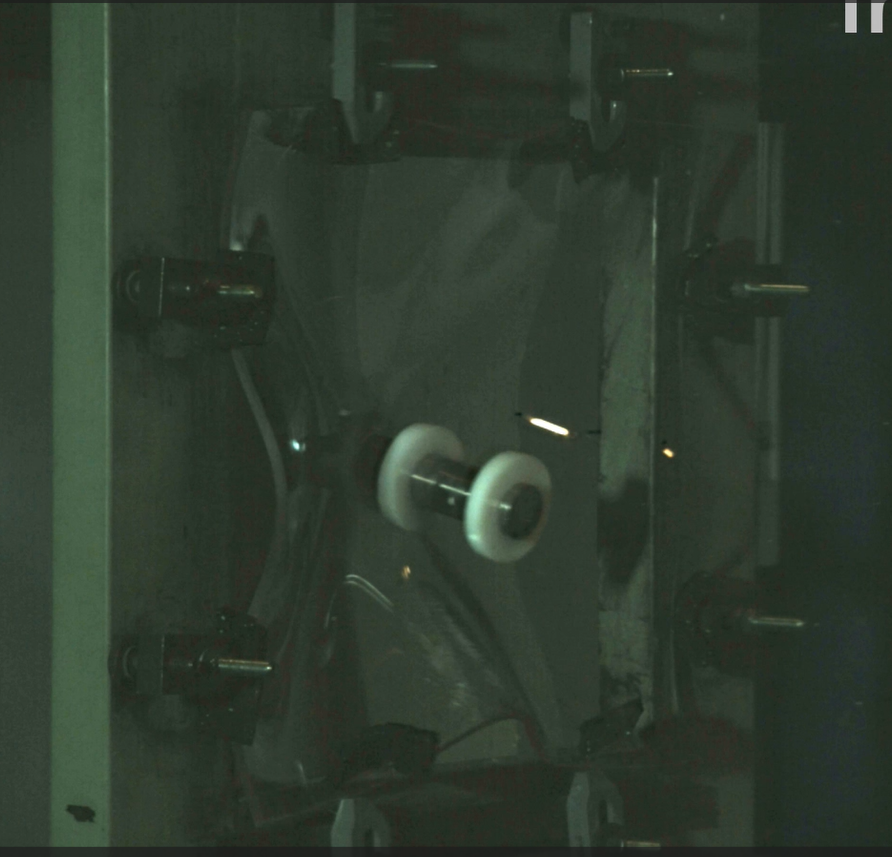

The test results alone are very impressive, but with ViewTec we decided to push our materials even further to the limit. We used a specific multi-axial impact resistance test setup, where the speed of a falling dart is kept constant during penetration. UV-curable coatings on polycarbonate would have resulted in embrittlement in this test setup, but not ViewTec’s. We are very proud of the fact that all our rigid coatings do not show any embrittlement, even in this test with very heavy impact.

To illustrate; the huge deflection of one of the samples (not ViewTec) after the multi-axial impact test performed at -40ºC.

No compromise on performance! That’s what ViewTec guarantees. Get in touch and we will be happy to help.

Goolderheideweg 11,

3950 Bocholt

+32 (0)89 46 93 30

info@zweko-optics.com

BE0840.886.961